In the current complicated situation, the volume of the product is controlled through various designs and the cost of shipping is reduced. This design can pack 3 times more than one 40HQ, which greatly saves the pressure of shipping costs. It can help you gain the key competitive advantage you need in a rapidly changing market.

The bag is a DIY design, this system is compatible with both the Stand bag and the Cart bag, both are compatible. First of all it is composed of four parts. 1. The inner liner is made of 14 full-length inner grids, and its bottom part has several magic buttons. 2. The chassis, there are several holes on the edge of the low plate, which can be combined with the magic buckle at the bottom of the inner tank. 3. The body, the body of the bag is an independent part, and there are magic buckles on the upper frame and the chassis; 4. There are some buckles around the head frame, which can be combined with the upper part of the inner tank, and the top and bottom are tightened to form the barrel body. The whole bag is very simple to assemble.

1. The inner part of the head frame

The inner grid of the head frame is completed first, and the bottom of the inner grid is fixed with the PE board, and the car is tight and loose.

2. The body part of the bag

After the bag is done, the car is ready, and the kit is assembled up and down.In the assembly process, place the head frame on the top of the bag, correspond to the component alignment bolts, and press from front to back, so that the card position is automatically stuck. There are 6 groups of card slots in the upper frame.After the head frame is assembled, turn the bag body over, pull the inner grid over from the bag body, find the mark position, and pull the elastic rope to the positioning hook in the lower frame in turn.

3. Chassis

Take the chassis and place it at the bottom of the bag. The alignment bolts of the corresponding components are pushed in by force in sequence, and the card position rebounds. There are 8 groups of card position combinations in the lower frame.

- Shipping a golf bag today has become costly.

- To reduce cost,we have broken down the golf bag and placed it into a smaller master carton reducing shipping cots by half.

FULLY BUILT GOLF BAG MASTER CARTON

SHIPPING SIZE:

36″H x 12″W x9″D(91.5H x30.5W x23D CM)

Container Quantity:872

KD GOLF BAG MASTER CARTON

SHIPPING SIZE:

33″H x 12″W x4.5″D(84Hx30.5Wx11.5DCM)

Container Quantity:1900

Stand Golf Bag Production Process

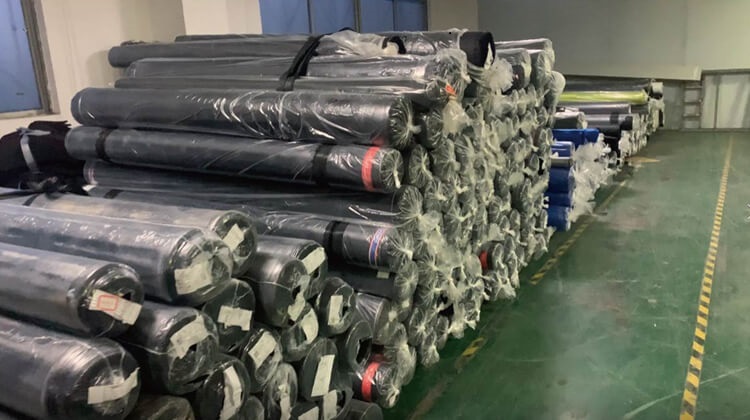

Raw material quality requirements:

1. The adhesion and flexibility of the PU material are normal. Slight rubbing of the paint surface will not cause whitening, breakage, blistering, and the wear resistance must meet the national standard. The surface of the PU material should not have cracks or cracks. There can be no yin and yang colors between them (except for some PU materials that have natural or multi-color effects). For the same golf bag, there should be no color difference or wrinkles between the PU materials.

2. Whether the fabric is knitted or woven, the fabric is required to be flat, not drawn, not knotted, and the color fastness is up to standard

3. The lining and webbing are rubbed 60 times with white cotton cloth, no fading, no desizing and no bleaching.

The appearance of the lining has no drawing, no turning, no missing yarn, no skipping, no hooking, no roving, no color difference, no belly yarn, no stain, no hole, no warp break, no crease, no wrinkle Phenomenon.

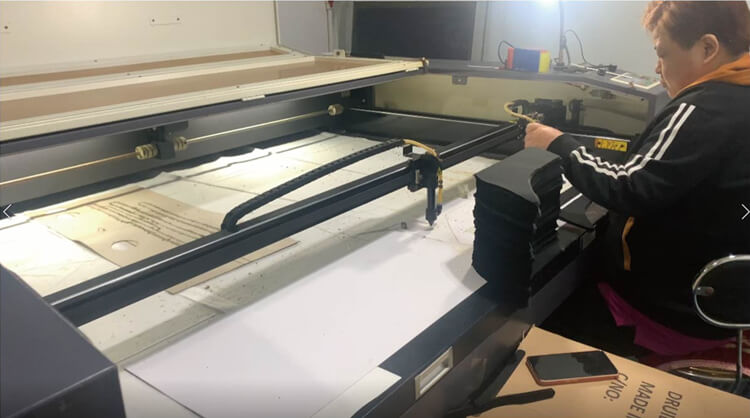

The various PU materials, nylon materials, etc. we use every day are actually made of a combination of many cut leather parts. In the beginning, these parts are all on the whole leather, in order to precisely cut the parts we need. At this time, one or more cutting dies must be used, and various cutting tools also have their suitable and unsuitable leather materials and shapes for cutting. Therefore, it is necessary to master the skills of cutting leather, and be familiar with it to be able to cut straight lines, curves and parts of various sizes and shapes freely and flexibly.

Cutting leather is a very serious matter, because once the cutting knife goes down, the leather cannot be recovered. The tools for cutting leather materials are mainly leather cutting knives, utility knives, molds or laser cutting, etc., and various tools also have their own characteristics. Easier to handle. But if you want to create your own unique and beautiful products, flexible use of various techniques of cutting operations is an indispensable skill for pattern makers.

Finally, some leather goods need to be lined with a lining. The lining is to fit two pieces of leather meat layers together, and more thin leather materials with a thickness of less than 1mm are used. After the adhesive dries, it is cut.

In order to make golf bag cutting more precise, we use laser cutting in some parts, laser cutting can cut a variety of designs with higher precision and accuracy, laser cutting can also produce high quality cuts and edges, usually no further cleaning, handling or finishing, thus reducing the need for its finishing process. This cutting reduces the amount of material wasted, thereby reducing material costs over time.

Sewing is a very important process in the garment production process, and different material requirements for ball bags also require different sewing patterns to meet. To sum up, the basic sewing seam can be roughly divided into: flat seam, button seam, inner overlock seam, outer seam, back and forth seam, partial pressure seam, seated seam, stuffed seam, rolled edge seam.

Fabric sewn, when the sewing direction is parallel to the weft direction of these fabrics, is generally less wrinkled. As a rule of thumb, diagonal seams do not wrinkle, most fabrics. Therefore, it is generally sufficient to avoid wrinkling as long as the seam is in the direction of the oblique angle 15 of longitude or latitude. Therefore, it is possible to consider the use of oblique cutting. If necessary, apply a smoothing agent to the fabric.

After strict raw material inspection, cutting, sewing, and quality inspection, the product will be packaged. Packing requirements, carton printing should be clear, all cardboard should be durable and not easy to break. There should be no deformation and the carton should be oriented the same way as the bag. Cartons should not be stacked too high. In order to keep the appearance of the ball bag from being squeezed, an inflatable bag is usually used to line the shape of the pocket to ensure that the appearance of the ball bag is straight.

Reviews

There are no reviews yet.